News

News

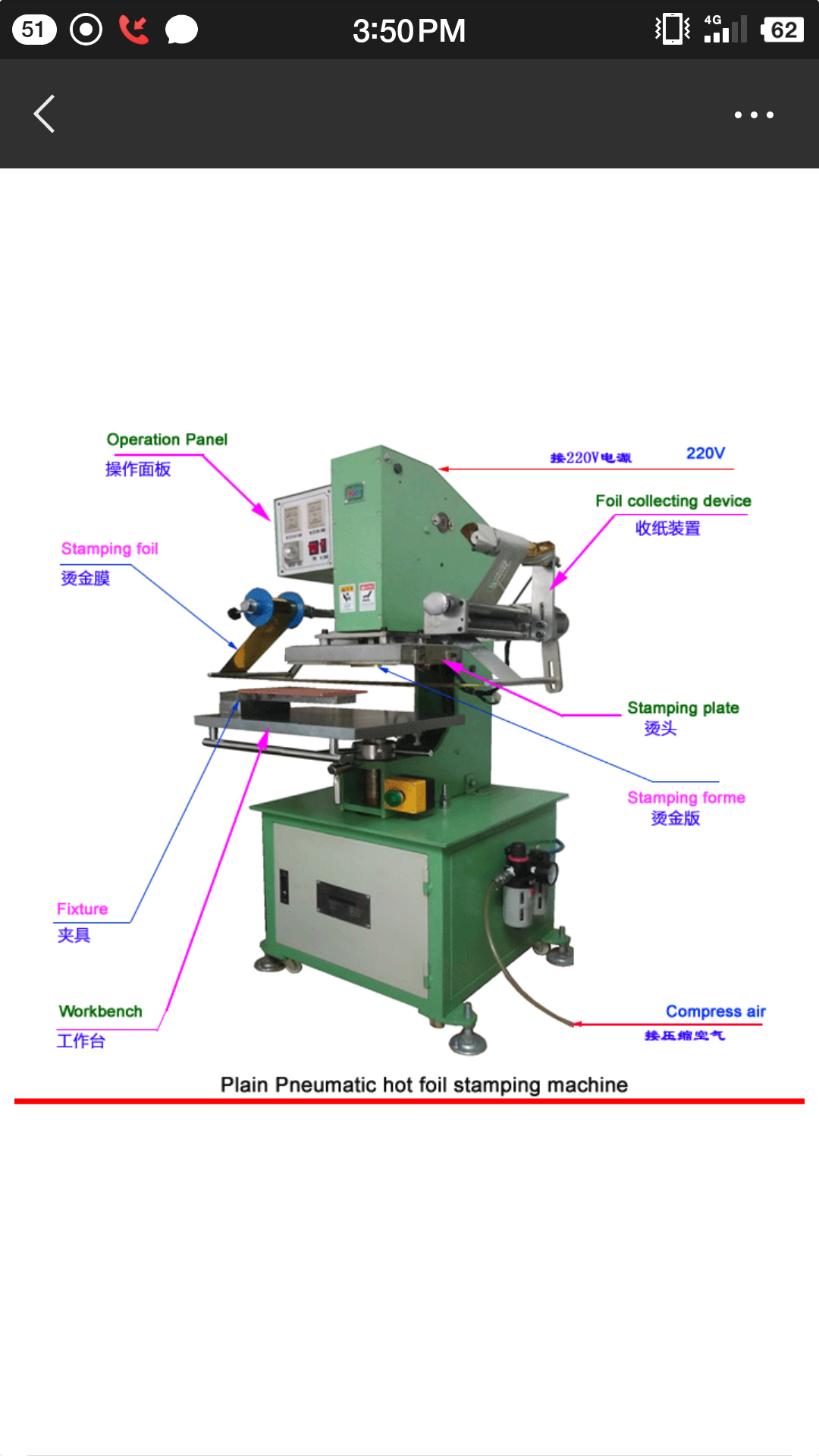

Hot stamping printer machine process for Paper-plastic composite packaging

2018-09-19

paper-plastic composite packaging and aluminum foil composite packaging are widely used in the field of product packaging. Most users will use the method of first hot stamping printing and then making bags. This technology is very suitable for the powerful packaging printing enterprises.

For the finished packaging bag to be stamped on the surface, it can be processed by plain semi-automatic Hot Stamping Machine. Although the speed is slow, but the equipment investment is small, it is no need for large-scale storage of packaging bags , so it can save costs.

Because the composite bag has two layers, the inner layer is often plastic film, so improper stamping process will cause adhesion between the

film, which is not conducive to product loading. So what kind of method can avoid adhesion between plastic films?

1)Inserting a silicon rubber plate with a certain hardness into the middle of the tea bag can avoid sticking to the two layers of the tea

bag.This silicon plate is fixed on the cantilever fixture. Considering the great pressure of stamping, the support structure is added under

the cantilever structure during the stamping process. The supporting mechanism can be controlled by pneumatic system.

After the workbench is removed, the paper bag is inserted, and then the workbench is moved into the stamping printing position. The

pneumatic structure controls the support structure to be jacked into the cantilever fixture, and then the stamping is carried out.

Althoughthe fixture is complicated, but it is more convenient to operate.

2)Tea bags contain paper-plastic composites materials as well as individual plastic film materials. Different types of Stamping Foil should be

used.

3) Both silicone plate and copper plate can be used to stamp paper bags. The pressure of silicone plate is easy to adjust, but the adhesion is not as good as engraving copper plate. The designs of engraving copper plates are more delicate and beautiful.