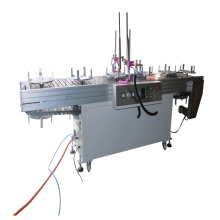

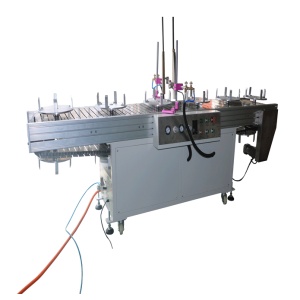

Paint bucket Plastics bucket flame treating machine

Unit Price: USD 3288 / Set/Sets

| Min.Order |

Unit Price |

| 1 Set/Sets |

USD 3288 / Set/Sets |

Model No.:SF250B

Applicable industry: Garment Shops, Building Material Shops, Machinery Repair Shops, Food &Amp; Beverage Factory, Retail, Construction Works

Out-of-warranty service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Where to provide local services (in which countries are there overseas service outlets): Philippines, Saudi Arabia, Indonesia, India, Mexico, Spain, Thailand, Japan, Australia, Morocco, South Korea, Colombia

Showroom location (in which countries are there sample rooms overseas): Philippines, Saudi Arabia, Indonesia, India, Mexico, Spain, Thailand, Argentina, South Korea, Uae, Colombia, Romania, Kazakhstan, Nigeria

Video factory inspection: Provided

Mechanical test report: Provided

Marketing type: Ordinary Product, New Product 2020

Core component warranty period: 1 Year

Core components: Engine, Motor

status: New

Types of: Conventional Plate Processor

degree of automation: Semi-Automatic

place of origin: China

warranty period: 1 Year

Core selling point: High Rigidity, High Safety Level, Sustainable, Remote Monitoring, Multifunctional

conveyor length: 2800mm

Packaging: Wooden case

Productivity: 10 sets/month

Brand: KC

Transportation: Ocean,Land,Air

Place of Origin: Dongguan

Supply Ability: 50

Certificate: CE

Port: Shenzhen,Guangzhou,Hongkong

Machine description

The printing of polyclinic materials often encounters the problem of ink shedding. The main reason is that it is composed of non-polar molecules. The printer will first choose a special polyclinic ink. If the adhesion of the ink does not meet the requirements, then Consider pre-treating the product surface, and flame treatment is a common and effective method.

The most suitable products for flame treatment are some cylindrical plastic bottles, and the effect is satisfactory no matter whether solvent-based ink or UV ink is used. The Flame Treatment Machine for plastic bottles is composed of a flame generating device and a conveyor belt. The conveyor belt is often equipped with a rotatable support cone. The bottle can be inserted into the cone and enter the flame treatment head with the conveyor belt. The inside of the flame treatment head is filled with compressed air and Combustible gas, after ignition, sprays out a flame with pressure, which can oxidize the surface of the bottle. For automatic Screen Printing Machines, flame treatment devices have almost become a standard configuration.

| SF250B Cylinder flame treatment Machine//Parameter |

| Technical parameters | - Flame width:250mm;

- Burning Gas:LPG gas;

- Conveyor speed:0~10m/min;

- Combustion gas:Compressed air 8kg/cm2 ;

- Bottle mouth diameter: 300mm;

- Distance between Support seat: 300mm;

- Max Bottle diameter: 100mm.

|

| Works supply | - Power: 1 phase 220V;

- 5-7bar compress air;

- Combustible gas

|

| Package list | - Dimension: 2.950×1.150×0.850m;

- Gross weight; 275KG;

- CBM: 2.8633

|

| H.S.Code | 8443198000 |

| Certificate | CE |

| SF250C Cylinder bucket Flame treatment Machine//Advantage |

| Function | - Mainly used for the surface pretreatment of PE and PP plastic products;

- Micro motor imported from Japan, stepless speed timing mode is adequate for different workpiece requirement;

- The machine is two sides equipped with baffle-boards to improve the heat efficiency;

- Advanced gushing nozzle is design generates a good combustion result, it is a product that saves energy;

- According to the size of your product that is to be printed, replace the taper support to meet the different requirement of workpiece

|

Machine Structure

Solution

Product Categories : Prepress Equipment > Flame Treatment Machine

Inquiry Basket ( 0 )

Inquiry Basket ( 0 )

Contact Now

Contact Now

Contact Now

Contact Now