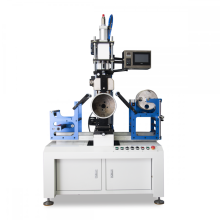

High quality Plain Heat Transfer Machine

Unit Price: USD 5800 / Set/Sets

| Min.Order |

Unit Price |

| 1 Set/Sets |

USD 5800 / Set/Sets |

Model No.:H-400M

species: Heat Press Machine

Applicable industry: Food &Amp; Beverage Factory, Food Shop, Printing Shops, Building Material Shops, Food &Amp; Beverage Shops, Retail

Out-of-warranty service: Video Technical Support, Field Maintenance And Repair Service, Online Support, Spare Parts

Where to provide local services (in which countries are there overseas service outlets): Thailand, Indonesia, Germany, Viet Nam, Pakistan, Malaysia

Showroom location (in which countries are there sample rooms overseas): United Kingdom, Philippines, India, Kenya, Algeria, Pakistan

status: New

Type of printing plate: Letterpress

place of origin: China

use: Cloths Printer

degree of automation: Semi-Automatic

Printing color number and surface number: Multicolor

warranty period: 1 Year

Core selling point: High-Accuracy

Marketing type: Hot Product 2019

Mechanical test report: Provided

Video factory inspection: Provided

Core component warranty period: 1 Year

Core components: Motor

Plate: Relief Printing

Color & Page: Single-Colour Printing Press

Species: Intermittent

Temperature Control: Heater Tube, Automatically Controlling

Foil Collecting: Automatically Collecting

HS Code: 8443198000

Packaging: Wooden case

Productivity: 10 Sets/month

Brand: KC

Transportation: Ocean

Place of Origin: Dongguan

Supply Ability: 30 Sets/month

Certificate: CE

Port: Shenzhen,Guangzhou,Hongkong

Samples

Thermal transfer printing on plastic materials is a special printing process, which is divided into two steps. First, the pattern to be transferred is printed on the PET film or BOPP film with a gravure printing machine, because the gravure printing machine is very easy. Multi-color printing with high aesthetics is achieved, and the pattern colors on the film are very rich and bright. Second, use a thermal transfer machine to transfer the pattern on the PET or BOPP film to the surface of the plastic product. Since the thermal transfer machine only needs a lower temperature and less pressure to achieve the transfer, the level loss of the graphic and text is very small. few.

Heat Transfer Film is usually outsourced to a specialized gravure printing machine factory, while the heat transfer process is completed by a special Heat Transfer Machine. The thermal transfer machine uses the principle of heat and pressure, uses a silicone roller or a flat silicone plate as a source of pressure and heat, presses the thermal transfer film tightly on the surface of the product and keeps it in contact for a period of time, the thermal transfer film is The pattern is completely transferred to the product.

The thermal transfer printing process is widely used in the printing of plastic containers, especially hoses, cups and barrels. In terms of color expression, the thermal transfer printing machine leaves a very deep impression on people.

H-400M Hydraulic heat transfer machine //Usage and characters - Suitable for large-area flat and cylindrical products of the thermal transfer process;

- The necessary heat transfer machine for everyday household items, household appliances, toys, plastic gift industry;

- Hydraulic structure design, the transfer process is more stable, more uniform pressure;

- Can transfer the graphic product, the installation of a round face, the fixture can transfer, cups and other round products on the work bench;

- Transfer machine, embossing machine, and there is no essential difference between the generally believed: sources of stress to the rubber roller machines belonging to the heat transfer machine, bronzing machine as the source of the pressure is a silica gel plate;

- Heat transfer machine can use the thermal transfer film, you can use foil paper, through the necessary transformation of the heat transfer machine can be installed on the copperplate roller to achieve the bronzing process;

- The bench stroke can be flexibly adjusted, suitable for the transfer of the products of different lengths;

- The roller width 400mm;

- Suitable for all types of plastic, glass, coating metal surfaces, wood, some ceramics and other kinds of material.

Application fields - Plastics thermal transfer;

- Woodware thermal transfer machine,stamping,

- Plastics Bronzing ,Glass and metal Heat transfer

- H-TC400M Hydraulic heat transfer Machine //Parameter

- Technical parameters

- Length of Rubber Roller: 400mm;

- Working table area: 1200 x 500 mm;

- Max pressure:3000 Kg;

- Up-and down distance: 100 mm;

- Table Stroke : 450 mm;

- Heat wattage: 3000 W;

- Foil feed: Motor Drive;

- Temperature range: 0 - 400oC;

- Net Weight :675 Kg;

- Max stamping diameter: 260mm

- Works supply: 3 Phase 380 V Power supply.

- Package size:1.98×1.23×1.80 m;

- Gross weight: 585 KG;

- CBM: 4.38372

- H.S.Code: 8443198000

- Certificate: CE

H-400M Hydraulic heat transfer machine //Advantage - The program controller, easy to operate;Uniform heat transfer, plastic roller rotation;

- Suitable for large-area stamping; plane or cylinder heat transfer can be achieved by installing a different fixture;

- High-precision photoelectric cell tracking control for easy positioning thermal transfer;

- Non-location requirements of stamping using a timed feeder by the length of the rolls can be flexibly adjusted;

- Adjustable worktable, easy to transfer the workpieces of different lengths;

- The transfer pressure, temperature, speed can be based on different material for the flexible adjustment;

- The nose height adjustable stamping head movements can fine-tune, easy to adjust the height of the different products;

- Precise temperature control system, temperature error control in less than 3 degrees; silicone roll radiant heating, thermal efficiency of the utilization factor;

- Rubber roller embossing pressure control system, constant pressure of the transfer process, the transfer effect is more perfect.

|

Product Categories : Hot Foil Stamping Machine > Heat Transfer Machine

Inquiry Basket ( 0 )

Inquiry Basket ( 0 )

Contact Now

Contact Now

Contact Now

Contact Now