| H-TC50KMA automatic bottle cap foil Heat Transfer Machine //Structure |

| Working table | 10 stations rotating workbench ; |

| Stamping Head drive | Pneumatic drive |

| Foil collecting method | Motor-drive , Collecting time adjustable |

| Press adjustment | Front-back of stamping head |

| Temperature control | Heating tube heat up,Automatically temperature controlling, temperature free setting |

| Stamping roller size | Width: 100mm, diameter: 125mm. |

| H-TC50KMA Automatic bottle kids foil heat transfer machine //Usage and characters |

| Guide | - Products suitable for large area flat and cylindrical products, thermal transfer process;

- Everyday household items, household appliances, toys, plastic gifts, etc. essential thermal transfer machines;

- Pneumatic structure design, the transfer process more stable, the pressure more evenly;

|

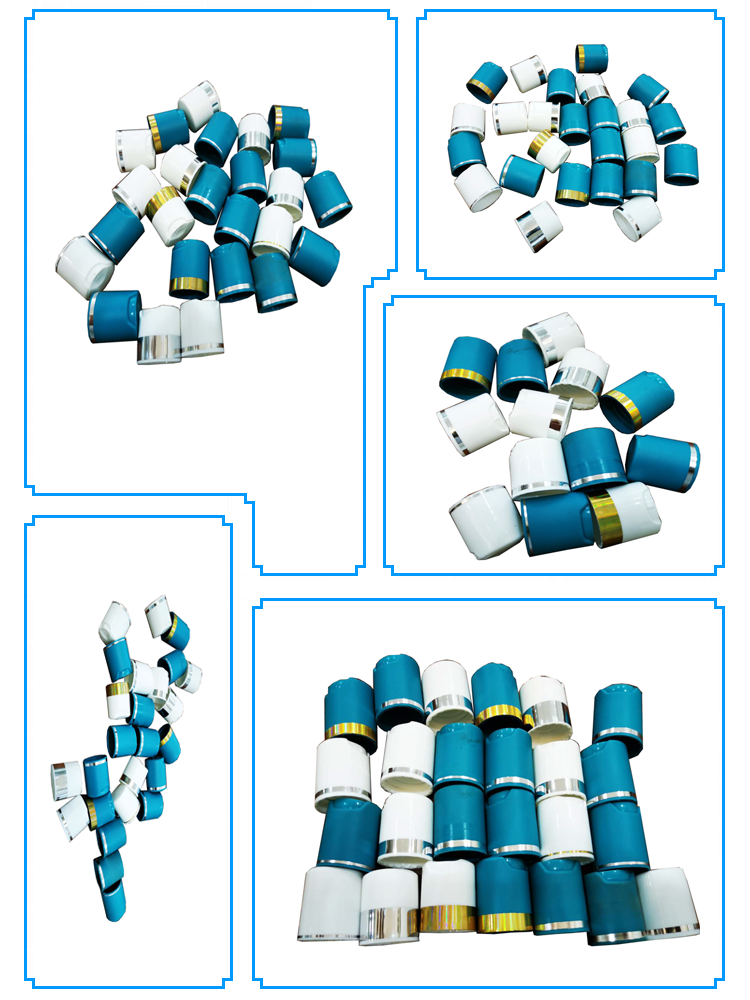

| Application fields | - Plastics thermal transfer;

- Woodware thermal transfer machine,stamping,

- Plastics Bronzing ,Glass and metal Heat transfer;

- All kinds of Round and irregular container cap, lid; cosmetic lids.

|

| H-TC50KMA automatic bottle caps foil heat transfer Machine //Parameter |

| Technical parameters | - Diameter of stamping roller :plate: 125×100 mm;

- Heater Wattage: 2000W;

- Stamping height adjustable range =100 mm;

- Max. stamping diameter: 50mm

- Stamping temperature adjustable range: 0 - 250oC;

- Stamping Foil pulling length: =150 mm;

- Stroke of Stamping Plate: 50 mm;

- Max. stamping pressure: 600 kgf (7bar);

- Max. stamping speed: 1100 pcs/hr;

- Air consumption: 100 litre/min;

- Dimensions: 1450 x1450 x 1300 mm;

- Weight: 465 Kg;

|

| Works supply | - 1 Phase 220V Power supply.

|

| Package list | - Package dimension:1.5×1.5×1.35m

- Gross weight: 439KG;

- CBM:3.296176

|

| H.S.Code | 8443198000 |

| Certificate | CE |

| H-TC50KMA Automatic bottle caps foil heat transfer machine //Advantage |

| Function | - The program controller, easy to operate;

- 10 stations rotating workbench,

- Uniform heat transfer, plastic roller rotation, suitable for cylinder heat transfer can be achieved by installing a different fixture;

- High-precision photoelectric cell tracking control for easy positioning thermal transfer;

- Non-location requirements of stamping using a timed feeder by the length of the rolls can be flexibly adjusted;

- Adjustable worktable, easy to transfer the workpieces of different lengths;

- The transfer pressure, temperature, speed can be based on different material for the flexible adjustment;

- The height adjustable stamping head movements can fine-tune, easy to adjust the height of the different products;

- Precise temperature control system, temperature error control in less than 3 degrees; silicone roll radiant heating, thermal efficiency of the utilization factor;

- Rubber roller embossing pressure control system, constant pressure of the transfer process, the transfer effect is more perfect;

- Bench design of the patented floating bodies, in accordance with the outline of the product line floating in the transfer process to maintain the Cots thermal transfer film or foil paper is closely attached to the surface of the product, and profiling Hot Stamping and Heat Transfer .

- Robot downloading, speed more fast.

|

Inquiry Basket ( 0 )

Inquiry Basket ( 0 )

Contact Now

Contact Now

Contact Now

Contact Now