Closed cup adopt closed cup ink supply system, avoid VOC volatile, suitable for Europe and american market , We provide various pad printer for industry area: Electron, Toys, hardware, gift, stationary, Auto parts, Mobile, computer, Plastics package, wooden, leather, rubber, Household appliances,Daily necessities, hotel supplies, Tourism supplies, cosmetic, office supplies.Photographic equipment, glasses supplies, Jewelry Accessories, Decorations, medical supplies, sports equipment, health products,ETC.

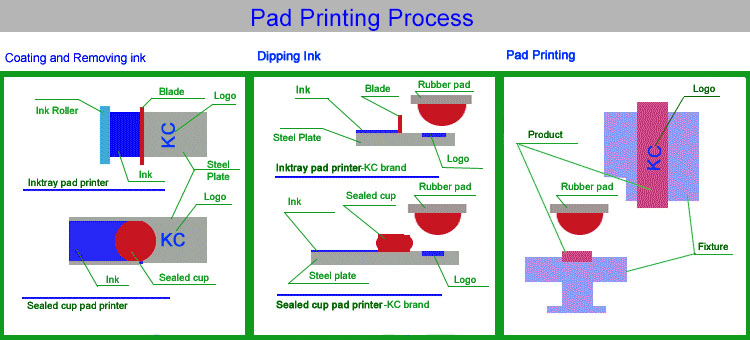

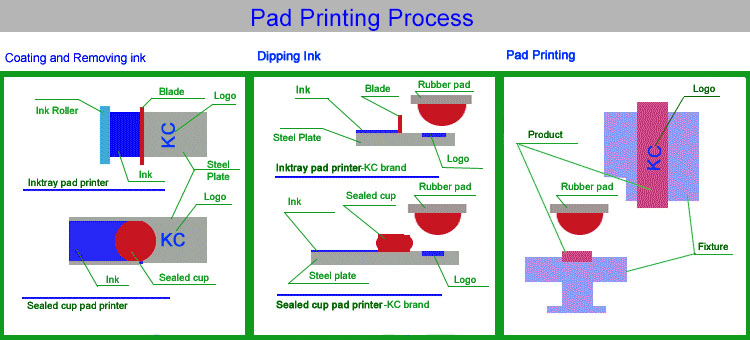

Pad Printing Process

1.Coating: Coating ink onto the pad plate by an ink roller or sealed cup

Opened-inktray pad printer stores ink in the end of the tray, when the roller slide into the ink and out will bring ink to the pad plate; sealed cup pad printer stores ink in the sealed cup. Sealed cup moves from back to forth and brings ink into the cave of pad plate.

2.Removing ink: Removing ink on the pad plate with steel blade or sealed cup

The ink in the cave of pad plate will remain. Removing the ink on the surface of pad plate completely is very important. when the ink remain on the surface of pad plate, pad will pick up them with the ink in the cave of pad plate, printing picture will be not same as standard document. Removing ink with steel blade on inktray pad printer and Removing ink with Sealed cup on Sealed cup pad printer.

3.Picking up ink

Pad above the pad plate press down and pick up the ink from the cave on the pad plate, then rise up. The ink will be transfered onto the pad surface because of pressure. Please make sure the size of rubber pad is matched with logo.

4.Moving:

Pad move to the position above the working table and substrate. There are two kinds of moving way: one is parallel moving, the other is turning moving. Most of KC brand pad printer drives with pneumatic -controlling.

5.Printing:

Pad press down to contact the substrate and print inks onto substrate. Substrate is installed on the fixture and the fixture is installed on the working table of pad printer.

Inquiry Basket ( 0 )

Inquiry Basket ( 0 )

Contact Now

Contact Now